Optimal Timing for Concrete Staining

Concrete stainings are most effective when applied under optimal weather conditions. Proper timing ensures durability, color vibrancy, and adhesion. Understanding the ideal periods for staining can lead to longer-lasting results and fewer issues related to weather interference.

Spring and fall are preferred due to moderate temperatures and lower humidity, which promote proper curing and adhesion.

Staining should be done when temperatures are between 50°F and 85°F to prevent issues like peeling or uneven color.

Avoid staining during rainy, freezing, or extremely hot periods to prevent moisture issues and color inconsistencies.

Concrete should be fully cured, typically 28 days after pouring, before staining begins.

Application during suitable weather ensures optimal results.

Temperature control is crucial for stain adherence.

Avoiding rain and extreme heat improves longevity.

Ways to make Concrete Stainings work in tight or awkward layouts.

Popular materials for Concrete Stainings and why they hold up over time.

Simple add-ons that improve Concrete Stainings without blowing the budget.

| Weather Condition | Recommended Timing |

|---|---|

| Rainy | Postpone staining until dry weather |

| Freezing temperatures | Avoid until temperatures rise above 50°F |

| Extreme heat | Perform during cooler parts of the day or season |

| High humidity | Delay until humidity levels decrease |

| Moderate temperatures | Ideal for staining |

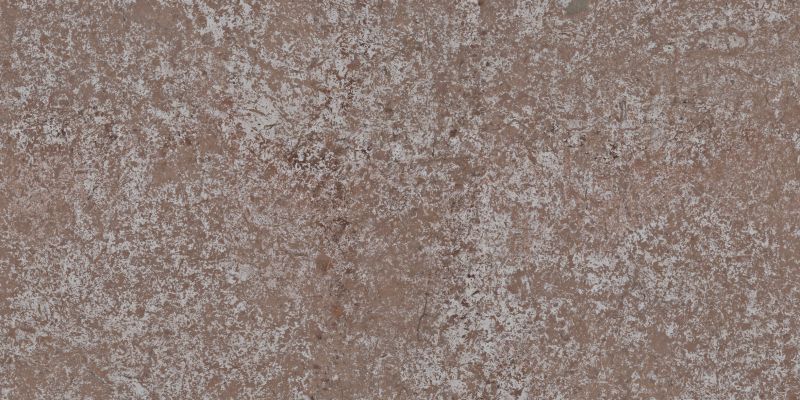

Concrete stainings enhance the appearance of concrete surfaces by adding color and depth. The process involves applying stains that penetrate the surface, creating a durable and vibrant finish. Proper timing, combined with surface preparation and suitable weather conditions, is essential for achieving high-quality results. Statistics indicate that staining can extend the lifespan of concrete surfaces by protecting against wear and weathering, making it a cost-effective choice for many applications.

A vibrant, durable surface ready for use.

Proper timing ensures even color distribution.

Different seasons yield different color effects.

Concrete must be fully cured before staining.

High-end options that actually feel worth it for Concrete Stainings.

Finishes and colors that play nicely with Concrete Stainings.

Little measurements that prevent headaches on Concrete Stainings day.

A 60-second routine that keeps Concrete Stainings looking new.

For those interested in concrete stainings, filling out the contact form can provide additional information and scheduling options. Proper timing and preparation are key to achieving the desired aesthetic and durability of stained concrete surfaces.